| This sequence is intended to answer one of the most commonly asked questions "What do you actually do to the engine".

After dismantling, all parts are thoroughly cleaned and inspected. We use two BUPI cabinet washing machines shown in the picture for chemical cleaning. Both use bio degradable aqueous solutions to clean components after dismantling and more importantly after machining and prior to painting.

A Hodge Clemco bead blasting machine is used for components that require more intense cleaning than the cabinet washers can provide. Such as corroded engine covers, carbonised cylinder heads etc. |

|

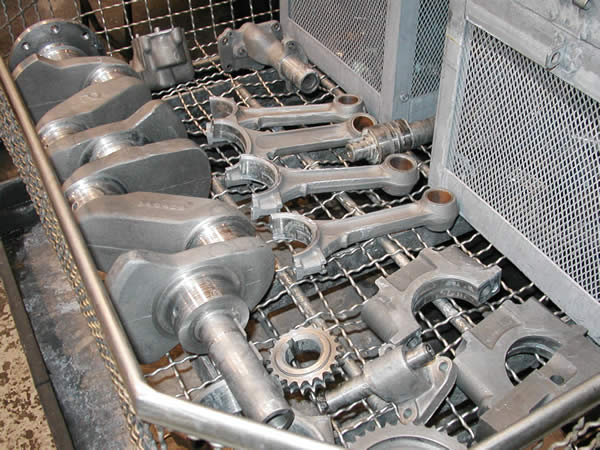

| Components in Bupi washing machine basket.

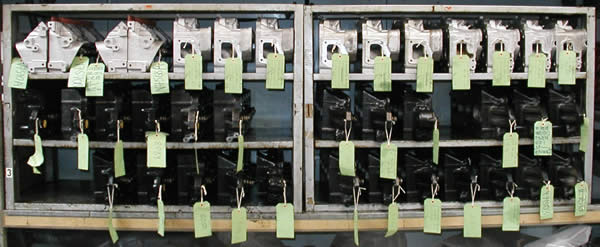

Large and smaller engine components (in baskets) after initial cleaning. At this stage, any damaged or scrap components can be rejected. Cleaned parts such as cylinder blocks and crankshafts are subject to non-destructive testing processes (crack and pressure test). Parts such as gaskets, core plugs, pistons, seals, bearings etc have been disposed of by this stage. |

|

| Overview of the machine shop.

Components subject to machining operations such as cylinder blocks, cylinder heads, crankshafts, connecting rods, rockers etc. travel through the machine shop under the control of our quality assurance system. |

|

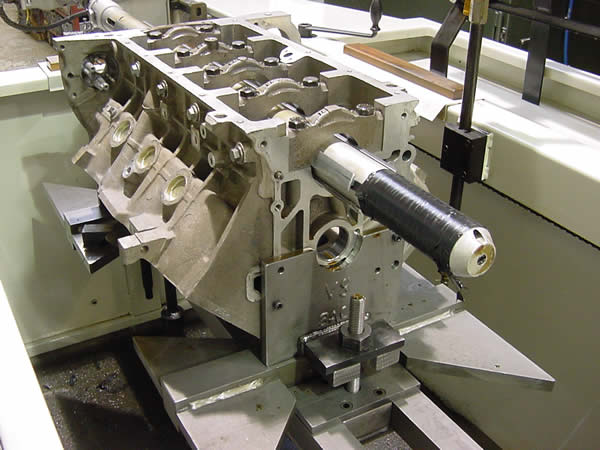

| This picture shows the CNC machining of a cylinder blocks. This is the most accurate process available.

The machine is a Mazak AJV 25/405N CNC jig borer. This machine was purchased new in the early 90's with a view to improving accuracy in machining and reducing time cycles on complex machining operations and is a vital part in our engine production.

4 cylinder block casting |

| V8 block casting |

|

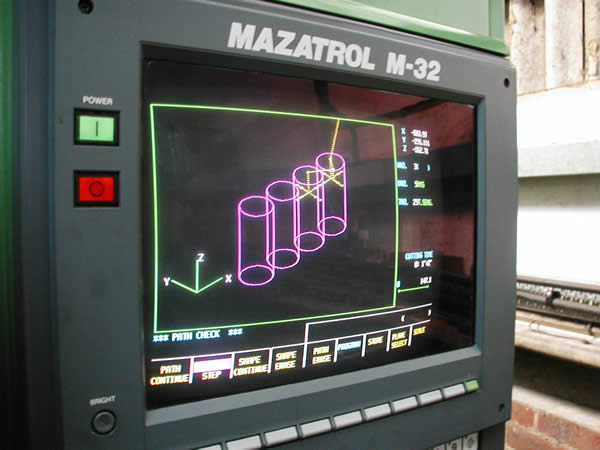

| Machining centre Mazatrol M-32 display

Some 30 programs are contained within the memory of the machining centre. Covering all metal cutting operations associated with cylinder bores, liners, cylinder head, block face, conrod and rocker bushes. |

|

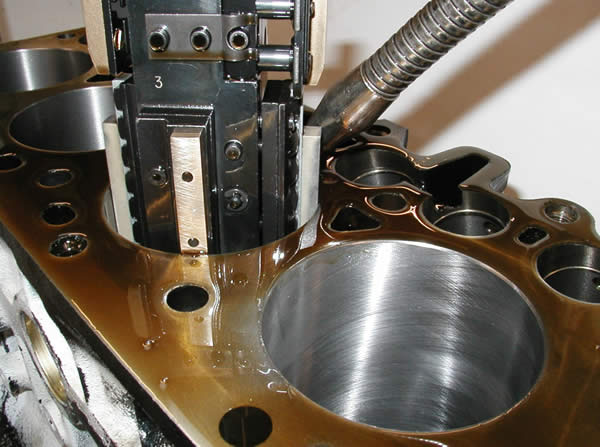

| Renishaw probing

Determining the exact position of where machining operations take place is established with the use of Renishaw probing.

This picture shows a connecting rod being measured.

|

|

| Accurate measurement of finished work is vital for the reliability of the re-manufactured engine.

Here a bore gauge is used for measuring connecting rod big ends after machining.

All vital measuring equipment used for final inspection is regularly calibrated in accordance with ISO 9001. |

|

| AMC1200U crankshaft grinder

Offset grinding of crankshafts: the preferred method. This is the same process as used in original manufacture and produces the best accuracy and surface finishes. |

|

| Reground three main bearing petrol journal.

Note the blended oil gallery and radius. This is the finished article, ready for assembly with the same surface finish and life expectancy as a new component. |

|

| AMC H260A vertical honing machine.

After boring, cylinders require honing to size to provide the correct running clearances specified by the piston manufacturers. We use a Sunnen CK3000 honing head. This machine is generally used for our four and five cylinder engines. |

|

| A close up of the Sunnen CK3000 honing head.

The correct surface finish is essential to ensure maximum performance, life expectancy and minimal oil consumption. Note the cross hatch markings on the cylinder wall. |

|

| Sunnen SV210 CNC vertical honing machine

Installed summer 2006, the machine is fully automated to work to extremely fine limits and has allowed increased production in line with increased demand for V8 engines.

This CNC honing machine is currently dedicated to our V8 engine block production.

|

|

| Sunnen SV210 CNC vertical honing machine.

Close up of the two stage diamond honing head. |

|

| Sunnen SV210 CNC vertical honing machine.

Close up of the control system. This control system allows the shape and size of the cylinder bore to be monitored as the cylinder is being honed. |

|

| Sunnen C100a horizontal line honing machine.

Line honing of cylinder block main bearing housings. This process covers the often ignored area of main bearing size, roundness and alignment, ensuring the life expectancy and smooth running of a new engine. |

|

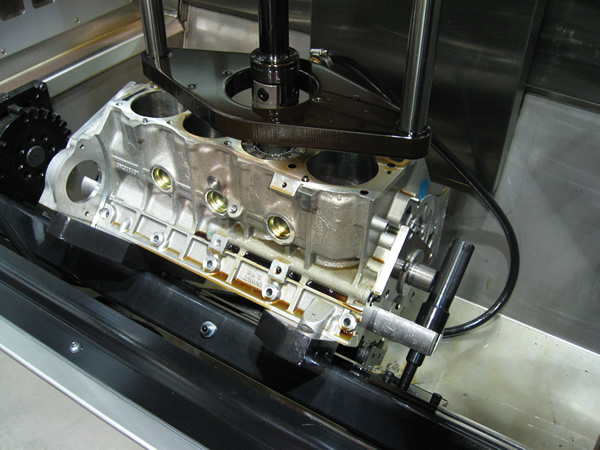

| 300TDI cylinder block.

The finished article ready for assembly, fully machined and painted.

During remanufacture the cylinder block has undergone the following processes: clean, crack test, fit new core plugs, inspect threads, pressure test. Fit new camshaft bearings and line ream. Line hone main bearing housings. Rebore/reline /hone cylinders, skim deck of block. Wash, flush oil galleries and paint. |

|

| The cylinder head department.

Fully equipped to produce cylinder heads. The Serdi 50 is used to produce counter bores for valve seat inserts, three angled valve seats and valve guide reaming.

A row of cylinder heads on the bench, awaiting machining. |

|

| Serdi 50 in action cutting a valve seat with three angled seat cutter.

We have supplied some 10.000+ cylinder heads for exchange and our re-manufactured engine program. |

|

| This picture illustrates the three angled seat cutting produced by our Serdi seat cutting system.

This system properly replicates the original seat specification essential for good performance and life expectancy. |

|

| A new 200 TDI diesel exhaust valve next to a newly cut valve seat.

The valve seating is checked with Engineers Blue to ensure a perfect seal and rechecked with a vacuum test to ensure reliable compression will be achieved. |

|

| A 2.25 petrol cylinder head assembled with new valves and springs.

The finished article, one of the several thousand lead free cylinder heads produced since unleaded fuel was introduced in 1986. One of our best selling products. |

|

| Close-up of the combustion area of a 2.25 lead free cylinder head illustrating the standard of workmanship and new valves used in the remanufacturing process. |

|

| A selection of petrol and diesel cylinder heads, ready for service. |

|

| Putting the finishing touches to a 200TDI engine.

If you've got this far, you have now seen evidence of heavy ongoing investment and commitment to quality throughout the production process.

We provide not just GOOD OR AVERAGE quality, but THE BEST quality product on the market today.

None of the products illustrated are new and have all been re-manufactured in our workshop, with the exception of valves.

Thank you for your interest in Turner Engineering.

|